04Dec

Running Thread – The Essential Fastening Solution for Your Projects

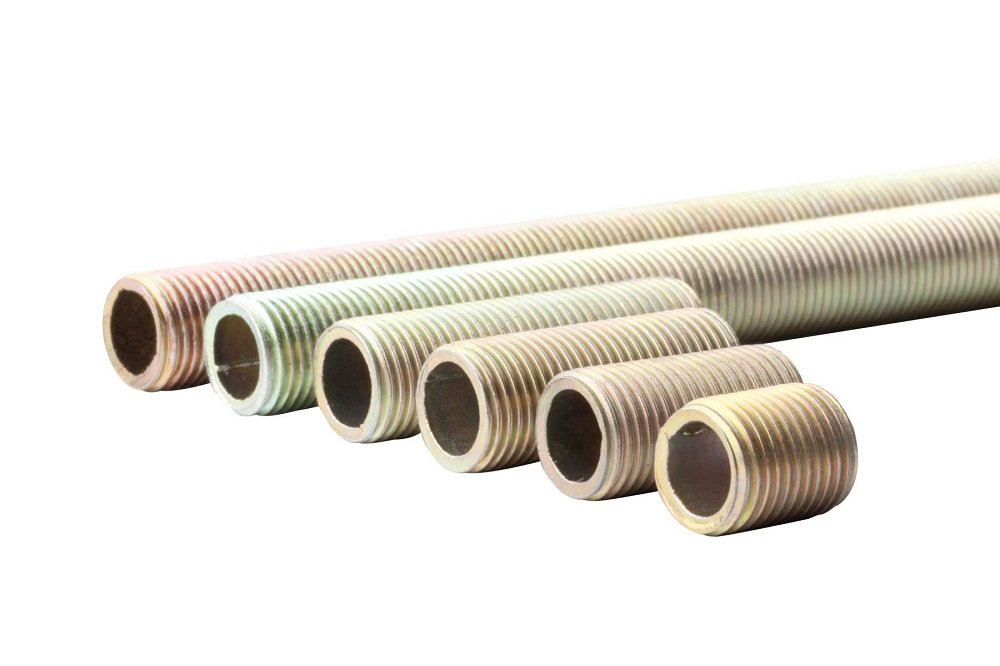

Running Thread: The Essential Solution for Construction and Industrial Projects

Running thread is a vital component in many construction and industrial projects, offering the flexibility and strength needed to secure materials and equipment. This continuous thread, often referred to as a full-threaded rod, is used in a wide variety of applications, from construction to manufacturing. In this post, we’ll explore the benefits of using running thread, how it’s applied, and where you can purchase high-quality running thread for your projects.

In construction and industry, the need for strong, reliable fasteners is essential. Running thread provides the ideal solution, offering continuous threads along the entire length of the rod, which allows for consistent fastening and securing. Whether you're working on a small-scale project or large infrastructure, running thread is an indispensable material.

Why Choose Running Thread for Your Projects?

Running thread is popular for its versatility and ease of use. Here are the key reasons why it’s often the preferred choice for fastening materials in construction and industrial applications:

- Continuous Threading for Consistent Fastening – Unlike standard bolts, running thread provides a continuous thread that runs the full length of the rod. This ensures that the fastener can be adjusted and tightened easily, providing consistent and secure connections.

- Flexibility in Application – The running thread can be used with a variety of nuts, bolts, and other hardware to secure materials. This versatility makes it suitable for numerous applications, from holding structural components in place to securing machinery.

- Strength and Durability – Running thread is made from high-quality materials such as stainless steel or carbon steel, offering excellent tensile strength. This ensures that the fastener can withstand significant loads and provide long-lasting performance.

- Cost-Effective and Easy to Use – Running thread is often more cost-effective than other types of fasteners due to its continuous design. It’s also easier to work with, reducing installation time and effort for your project.

- Corrosion Resistance – Many running threads are treated with coatings, such as galvanization, to provide protection against rust and corrosion. This makes them ideal for use in harsh environments, ensuring longevity and reliability.

- Construction Projects – Running thread is widely used in construction for securing structural components such as beams, columns, and foundations. Its continuous threading makes it easy to adjust and tighten, ensuring a strong, stable structure.

- Industrial Machinery – In manufacturing and industrial sectors, running thread is used to secure heavy machinery, pipes, and equipment. The durability and strength of the material ensure that these fasteners can handle the demands of industrial environments.

- Automotive and Aerospace – Running thread is also commonly used in the automotive and aerospace industries. The precise threading ensures that components are securely fastened, which is essential for the safe operation of vehicles and aircraft.

- Outdoor Installations – Running thread is ideal for outdoor projects, including the installation of fencing, lighting, and other structures exposed to the elements. The corrosion-resistant coatings on many running threads help protect them from moisture, ensuring their longevity.

- DIY Projects – For smaller-scale DIY projects, running thread provides an accessible and reliable fastening solution. Whether it’s for creating custom furniture or securing garden structures, running thread offers great flexibility and strength.

- Threading – The rod is first cut to the desired length and then passed through a threading machine. This machine creates the continuous thread that runs along the entire length of the rod.

- Heat Treatment – Depending on the material used, the rod may undergo heat treatment to increase its strength and hardness. This step ensures that the running thread can handle the demands of its intended application.

- Coating – To enhance the corrosion resistance of the running thread, a protective coating, such as galvanization, may be applied. This ensures the fastener can withstand exposure to moisture, chemicals, and other environmental factors.

- Inspection – After the threading and coating process, the running thread is carefully inspected to ensure that it meets quality standards. Any defective rods are removed from the production line to guarantee that only the highest quality products reach customers.

All Categories

- 1w

- 1Win AZ Casino

- 1win casino spanish

- 1win fr

- 1win India

- 1WIN Official In Russia

- 1win Turkiye

- 1win uzbekistan

- 1winRussia

- 1xbet

- 1xbet apk

- 1xbet arabic

- 1xbet Bangladesh

- 1xbet casino BD

- 1xbet india

- 1xbet Korea

- 1xbet KR

- 1xbet malaysia

- 1xbet Morocco

- 1xbet pt

- 1xbet RU

- 1xbet russian1

- 22bet

- 22Bet BD

- 22bet IT

- 888starz bd

- Anchors

- austria

- aviator

- aviator brazil

- aviator casino DE

- aviator casino fr

- aviator IN

- aviator ke

- aviator mz

- aviator ng

- b1bet BR

- b1bet brazil

- Bankobet

- Basaribet

- bbrbet colombia

- bbrbet mx

- bizzo casino

- Bolts and Nuts

- book of ra

- book of ra it

- Brand

- business

- casibom tr

- casibom-tg

- casino

- casino en ligne argent reel

- casino en ligne fr

- casino onlina ca

- casino online ar

- casinò online it

- casino svensk licens

- casino zonder crucks netherlands

- casino-glory india

- Clamps

- Clevis Hangers

- Concept

- Construction

- Continuous Thread

- crazy time

- csdino

- design

- developing

- Drillbit

- Energy

- events

- Expansion Shield

- Fair Go Casino

- fortune tiger brazil

- Gama Casino

- Game

- glory-casinos tr

- Hangers

- Hexbolts

- hobby

- Industry

- Jack

- KaravanBet Casino

- Kasyno Online PL

- king johnnie

- lifestyle

- Maribet casino TR

- Masalbet

- Maxi reviewe

- mini-review

- Mini-reviews

- Modern

- mombrand

- mono brand

- mono slot

- Mono-brand

- monobrand

- monobrend

- monogame

- monoslot

- mostbet

- mostbet GR

- mostbet hungary

- mostbet italy

- mostbet norway

- mostbet ozbekistonda

- Mostbet Russia

- mostbet tr

- Mr Bet casino DE

- mr jack bet brazil

- mx-bbrbet-casino

- Nelson

- news

- online casino au

- onlone casino ES

- ozwin au casino

- pelican casino PL

- Pin UP

- Pin Up Brazil

- Pin UP Online Casino

- Pin Up Peru

- pinco

- Plinko

- plinko in

- plinko UK

- plinko_pl

- Policies

- Qizilbilet

- Ramenbet

- Review

- Reviewe

- reviewer

- ricky casino australia

- Running Thread

- Sag Rods

- Scaffoldings

- science

- Screws

- skills

- Slot

- Slots

- Slots`

- slottica

- Stud

- sugar rush

- sweet bonanza

- sweet bonanza TR

- technologies

- Threaded Rods

- Tie Rods

- U-Bolt

- U-Head

- Uncategorized

- verde casino hungary

- verde casino poland

- verde casino romania

- Vovan Casino

- vulkan vegas germany

- Wingnuts

- Комета Казино

- Макси-обзорник

- сателлиты

Recent Posts

MON-SAT 8:00-9:00

+91 69 863 6420